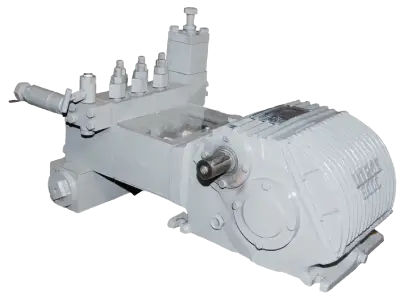

High Pressure Triplex Plunger Pumps

UTPSL offers High Pressure Triplex Plunger Pumps for a wide variety of industrial applications. Products of intensive research and development, the UTPSL series plunger pumps are designed to achieve high standards of performance and reliability to withstand continuous duty operations & guarantee smooth and trouble free performance.

Constructional Details

The pump can be driven by TEFC Non flame proof / Flame Proof electric motor with Star Delta / DOL Starter , also offered with Soft Starter / VVVF Drive / Flame Proof Panel .Pump with Diesel Engine ,manufactured as per requirement.

Compact Design , rugged construction pump with quieter operation.

Variation in flow & pressure possible by simple change of conversion kit.

Pump being manufactured on Base Frame with anti vibrationpads also mounted on Solid Wheel / Pneumatic wheel trolley for easy movement.

Pump Head

The forged stainless steel SS-410/SS-420/SS-431/SS-304/SS-316 pump-head , duly Ultrasonically tested, accurately machined on CNC machines is suitable for safe operation . For special application other materials such as nickel plated steel are also available.

Three type of Fluid end are being used for different pressure range .

Flat Head A-Type

Used for High Pressure ( up to 1500 bar ) –Low discharge , used for high pressure water jet cleaning / cutting for sticky scale ,concrete cutting etc

Step Shaped Pump Head

Used for Medium Pressure ( approx. 500 bar ) –Medium Flow , allows direct access to identical & interchangeable suction & discharge valves without having to disconnect suction or discharge piping.

Flat Head C-Type / M-Type Pump Head

Used for Low Pressure ( approx. 300 bar ) –High Flow , allows direct access to identical & interchangeable suction & discharge valves , to meet customer requirement.

Crank Shaft

The forged alloy steel , duly ultrasonically tested , machined with accuracy , supported by heavy cylindrical roller bearing and driven by means of Built in Helical gears & pinion shaft drive with Herring bone Gear arrangement.

Crank Shaft driven with Pulley & Belt arrangement & with external gear box can be supplied.

The Ductile Connecting rod links have replaceable steel backed Bi-metallic bearing.

Lubrication of Bearings

Splash lubrication for intermittent operation.

Forced lubrication for continuous dduty operation.

Plungers

High surface finish ceramic plungers increase life of seals.

Carbide plungers for special applications.

Packings

High Pressure seal packaging of Aramid -Teflan offer least resistance & plungers.

Pressure Regulator

Flange mounted pressure regulator manufactured from forged steel with stepless adjustment from zero to max.

Safety Valve

Spring loaded safety valve provides protection against overload.

Features and Advantages

Faster cleaning than conventional cleaning like brushing , chemical , mechanical etc.

Require less man power

Reduce shut down time

Safe operation

Environment friendly operation

No Chemical used, only water is the cleaning agent

Do not damage equipment / tube

High Possibility to clean equipment without dismantling thus saving precious time and cutting costs.

Other Accessories – High pressure delivery hose , High Pressure Gun , Dump , Gun , Foot operated Valve , Dump Foot operated valve , NRV, Pneumatically operated NRV cum bypass valve , electrically operated bypass valve , Flexible lance , rigid lance , pipe cleaning nozzles , round jet flat jet nozzles ,

Aquablast cleaning system ,

descaling headers, Rotory nozzles , spin jet nozzles etc

Hydro jetting and Cleaning of

Turbine blades,

Heat exchanger pipes and tubes,

Air-filters,

Pre-heaters,

Reactors,

Pressure vessels,

Silos,Tanks,

Machined parts,

Sewage pipes,

Ship hull,

Evaporators,

Condensers,

Coolers,

Tube Bundles,

Coach / Boggies,

External Surface,

Mould

Snowman

Cyclone Jam

Descaling of

Billets,

Blooms,

Plates,

Spring Sheets,

Forgings,

Pipes,

Non Ferrous Metals

Water Injections,

Accumulator Charging,

Hydro Testing,

Concrete Cutting,

Paint stripping,

Rust removal,

Oeburring,

Reverse Osmosis,

Water Hydraulics,

Prop supports Goose neck Cleaning,

Surface preparation,

Industries

Airports,

Aluminum,

Automobile,

Cement,

Chemical & Fertilizers,

Construction,

Forging,

Foundries,

Jute,

Metallurgical

Plants,

Mining,

Milk & Food Processing,

Municipalities,

Oil Refineries,

Paper & Pulp,

Petrochemical Plants,

Railways,

Ship Building,

Shipping,

Steel,

Sugar,

Thermal Power Plants and many more.