Grit Cleaning

GRIT CLEANING SYSTEM

Removal of Paint from Paint shop grits is being done manually by the following conventional methods which are time consuming and not effective

Removing the grits from paint booth

Transport the grits from paint booth to a distant place (As it involves lot of pollutions).

Burning / Scrapping the grits

Wash the grits with water

Transport back the grits to paint booth

Fix the grits in the paint booth.

DISADVANTAGES OF EXISTING SYSTEM

Highly labour intensive and therefore needs lot of manpower

Burning of grits creates environmental problems

Time consuming

Needs stand by grits, hence requires more capital

After burning & cleaning the grits, dust enters the painting booth hence paint booths are not dust free.

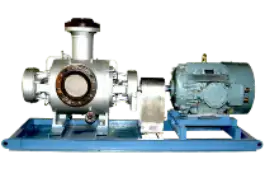

PROPOSED METHOD BY HIGH PRESSURE JETTING PUMP WITH UTPSL AQUABLAST.

UTPSL has developed special technology to use high pressure water jetting in conjunction with Aqua Blast system for cleaning of grits in place in paint booth itself. The aquablast has 4 nozzles with the rotary joint, which rotate by the reactional force created by water coming out of strategically placed nozzles at angles. The aqua blast moves on the grits having two solid wheels and one swivel wheel for easy handling. The jet at the bottom cleans the grits during operation.

The nozzle height can be adjusted with lever at the top, for proper cleaning. The aquablast system consists of By Pass Valve, operated with lever for easy operation during cleaning grits.

The working pressure 500-600 Bar required for cleaning grits depends upon the grit conditions. The ideal High Pressure pump shall have capacity of 84 LPM, powered by 110 KW motor /Diesel Engine.

The rate of cleaning shall be approx 1-2 square meter per minute depending upon the surface.