Descaling Systems

Descaling Systems

Descaling systems are engineered to deal with the oxidation/scaling that occurs during high temperature operations in steel and other metal manufacturing industries. This layer of oxidized scale can fuse with the base metal during the rolling process, compromising surface quality and mechanical properties.

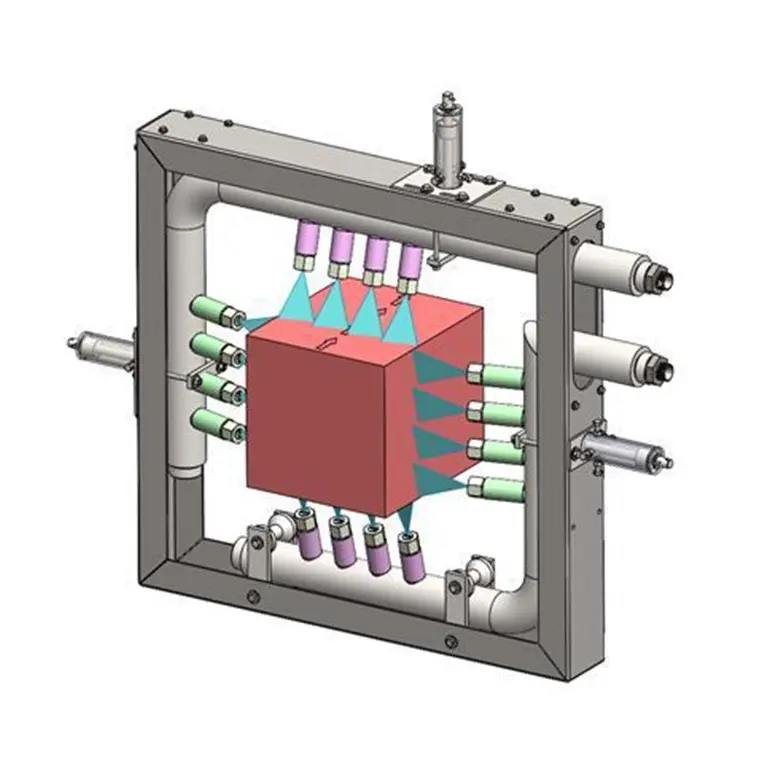

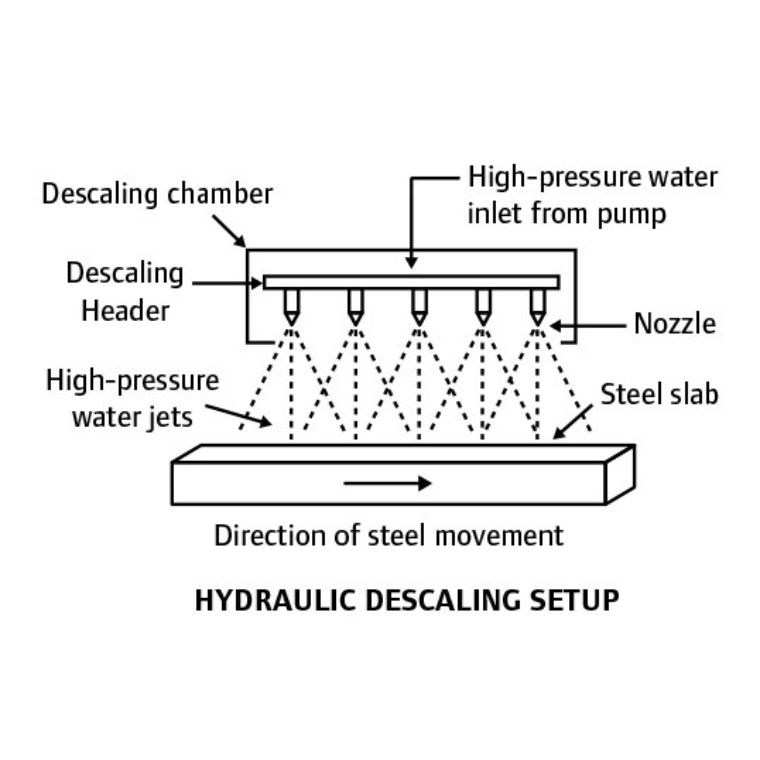

High-pressure water descaling systems feature strategically positioned nozzles at various angular orientations that deliver intense water jets directly at the interface between the scale and the base material.

This Process:

- Rapidly cools the scale, inducing thermal shock

- Loosens the scale layer from the surface

- Washes away the dislodged scale using high-pressure water

This ensures a clean, scale-free surface, optimizing the rolling process, and improving the final product quality.

Two Types of Descaling Systems

| Industries | Applications |

|---|---|

|

Steel & Metal Manufacturing

|

Billets |

| Blooms | |

| Slabs | |

| Plates | |

| Parabolic Springs | |

| Seamless Pipes | |

| Specialty Steel & Alloy Processing | Strips |

| Non-ferrous Metal Manufacturing | Profiles |

- Enhanced surface quality

- Maximized throughput and operational efficiency

- Extends the life of rolling mills, dies, & tools

- Reduced operational downtime

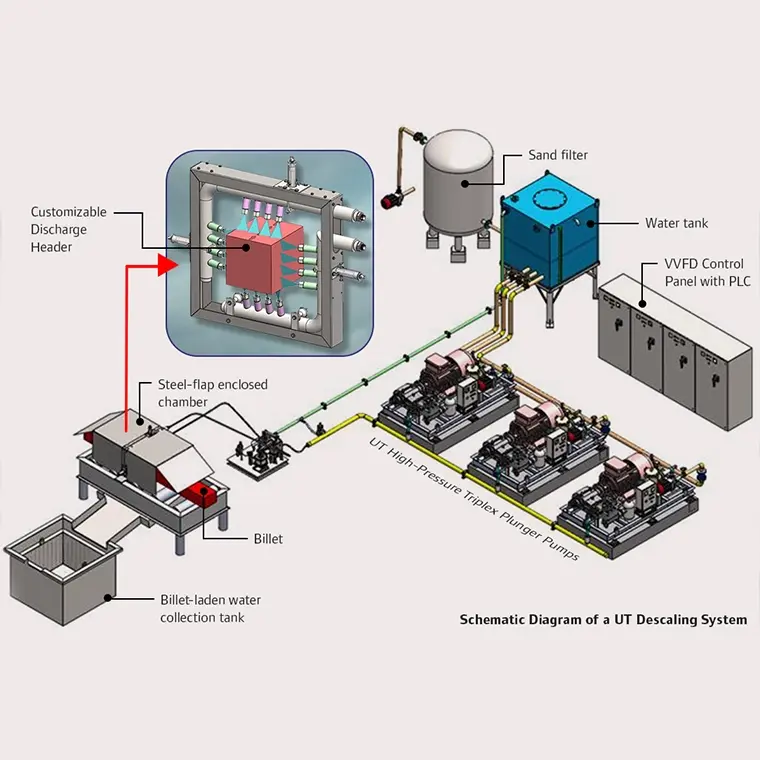

The UT Descaling System consists of the following key components, each designed to ensure efficient and precise scale removal from hot metal surfaces:

- UT High-Pressure Triplex Plunger Pumps

- Adjustable Descaling Header

- Solenoid-Operated Pneumatic NRV with Bypass Valve

- Hot Metal Detector

- Pressurized Water Tank with Level Control

- Sand Filter Unit

- PLC-Controlled Electrical Panel

- Interconnecting Pipelines and Valves

- Safety & Process Control Features

- Variable Voltage Frequency (VVVF) Drive