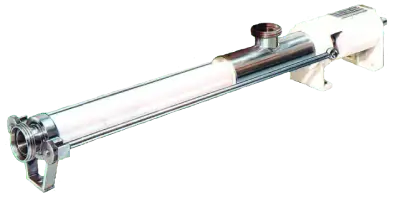

Single Screw Pumps ES Model

Applications

For Transfer of Chocolates Mix, Malt Extract, Syrups,

Honey, Minced Meat, Infant Food, Jams, Spices, Fresh

Cream, Butter, Condensed Milk, Fruit Juices & Pulp,

Purees, Jelly, Glucose, Beverages, Beer, Ice-Cream,

Vitamins Solution etc.

Basic Design, Principle of Operation

UTPSL Eccentric Helical Rotor Pumps are Self Priming,

Rotary, Valve less Positive Displacement pumps having

two pumping element Rubber Stator and Metallic Rotor.

Stator is having helical profile with pitch double to Rotor

pitch resulting in cavities, which carry the liquid.The basic

design of S type pump is a special pump designed with

two external tension rods being fastened at the bearing

housing to the pump casing. Type "S" means quick

cleaning, as the complete pump can be disassembled

with effortless ease and a biologically complete cleaning

of each part is possible. ES types of pumps are ideally

suited for Food and Milk Processing industries.

The suction and discharge port is provided with thread

pipe connection so that quick disassembly of pipe and

hose on suction and discharge side of pumps can be

done. Pumps are suitable for drive by Motor/Engine thro

Direct Coupling or V' Belt/Pulley.

In the Cross-section, stator and rotor contact each other at

two points which, viewed axially, are lines of contact or

“sealing”.

When the rotors turns, this geometry resolves into tandem

chamber which are self-contained as also when pumps

are stationary.

Industries

Food and Food Processing Industry, Beverages,

Breweries, Color & Varnish Factories, Confectioneries,

Dairy and Dairy Products, Cosmetics, Pharmaceuticals,

Oil Mills, Chemical Industry.

Materials of Construction

Pumps are manufactured specifically to meet modern

requirements for maximum hygiene. All parts coming in

contact with liquid are fabricated in smooth and fine finish

which ensures quick and complete cleaning of pump in

least stoppage time.

Wetted casings are available in rust & acid proof stainless

steel. Rotors are available in stainless steel, CrNi steel or

hard chrome plated for abrasive materials. Stators are

available in special types of elastomer material, which is

of food quality. Sealing of hygienic quality materials as

gland packing or mechanical seal is available.

UTPSL pumps are having two special design Cardon

joints completly sealed against liquid.

Because of Elastomer Stator, ES pumps are not

suitable for dry running.

Special Features / Advantages

Longer Pitch and smaller diameter of rotor makes

UTPSL pumps highly reliable with Small Initial Starting

Torque, Higher Mechanical Efficiency, Capability To

Handle Large Proportion Of Solids, Small Radial Thrust,

Low Rubbing Velocity, Less Wear, Lower Axial Thrust,

Smaller Unbalance, Quieter Operation, Quick

Cleanable, Disassembled with Effortless Ease.

Quick cleaning pumps with Pumps casing having special profile.

Pumps are ideally suited for milk and food processing industry.

Complete pump can be disassembled with effortless ease and biologically complete cleaning of each part is possible.

Special design sealed long life cardon joint

Capacity Range Available : - 5 LPM to 1450 LPM

Pressure range 12 Bar max.

Advantages of ES Pump

Available in food grade material combinations suitable for handling food products.

Available in different inlet/ outlet connection with dairy / food grade fittings.

Suitable for shear sensitive liquids thus maintaining the composition of product being pumped.

| Type | Max Pressure | Capacity Flow (m3/Hr) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 164 | 236 | 375 | 600 | 1024 | 1500 | 1900 | 2650 | 4500 | 6300 | ||

| ES | 6 | 4.2 | 9 | 13.8 | 24.1 | 27 | 61.7 | 90 | 103.5 | 192 | 278.1 |

| E2S | 12 | 2.1 | 4.5 | 6.8 | 11.3 | 13.7 | 28.5 | 42.4 | 52.2 | 9 | 141 |

Performance parameter given in above chart is indicative, Please Contact for actual Pump selection.